forum

library

tutorial

contact

Tiny Structure Gives

Big Boost to Solar Power

by Princeton University

R&D Magazine, December 7, 2012

|

the film forum library tutorial contact |

|

Tiny Structure Gives

by Princeton University

|

Princeton University researchers have found a simple and economical way to nearly triple the efficiency of organic solar cells, the cheap and flexible plastic devices that many scientists believe could be the future of solar power.

Princeton University researchers have found a simple and economical way to nearly triple the efficiency of organic solar cells, the cheap and flexible plastic devices that many scientists believe could be the future of solar power.

The researchers, led by electrical engineer Stephen Chou, were able to increase the efficiency of the solar cells 175% by using a nanostructured "sandwich" of metal and plastic that collects and traps light. Chou says the technology also should increase the efficiency of conventional inorganic solar collectors, such as standard silicon solar panels, although he cautioned that his team has not yet completed research with inorganic devices.

Chou, the Joseph C. Elgin Professor of Engineering, says the research team used nanotechnology to overcome two primary challenges that cause solar cells to lose energy: light reflecting from the cell, and the inability to fully capture light that enters the cell.

With their new metallic sandwich, the researchers were able to address both problems. The sandwich -- called a subwavelength plasmonic cavity -- has an extraordinary ability to dampen reflection and trap light. The new technique allowed Chou's team to create a solar cell that only reflects about 4% of light and absorbs as much as 96%. It demonstrates 52% higher efficiency in converting light to electrical energy than a conventional solar cell.

That is for direct sunlight. The structure achieves even more efficiency for light that strikes the solar cell at large angles, which occurs on cloudy days or when the cell is not directly facing the sun. By capturing these angled rays, the new structure boosts efficiency by an additional 81%, leading to the 175% total increase.

Chou says the system is ready for commercial use although, as with any new product, there will be a transition period in moving from the lab to mass production.

The physics behind the innovation is formidably complex. But the device structure, in concept, is fairly simple.

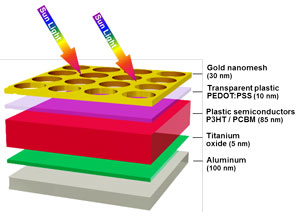

The top layer, known as the window layer, of the new solar cell uses an incredibly fine metal mesh: the metal is 30 nm thick, and each hole is 175 nm in diameter and 25 nm apart. This mesh replaces the conventional window layer typically made of a material called indium-tin-oxide (ITO).

The mesh window layer is placed very close to the bottom layer of the sandwich, the same metal film used in conventional solar cells. In between the two metal sheets is a thin strip of semiconducting material used in solar panels. It can be any type -- silicon, plastic, or gallium arsenide -- although Chou's team used an 85-nm-thick plastic.

The solar cell's features -- the spacing of the mesh, the thickness of the sandwich, the diameter of the holes -- are all smaller than the wavelength of the light being collected. This is critical because light behaves in very unusual ways in subwavelength structures. Chou's team discovered that using these subwavelength structures allowed them to create a trap in which light enters, with almost no reflection, and does not leave.

"It is like a black hole for light," Chou says. "It traps it."

The team calls the system a "plasmonic cavity with subwavelength hole array" or PlaCSH. Photos of the surface of the PlaCSH solar cells demonstrate this light-absorbing effect: under sunlight, a standard solar power cell looks tinted in color due to light reflecting from its surface, but the PlaCSH looks deep black because of the extremely low light reflection.

The researchers expected an increase in efficiency from the technique, "but clearly the increase we found was beyond our expectations," Chou says.

The researchers say the PlaCSH solar cells can be manufactured cost-effectively in wallpaper-size sheets. Chou's laboratory used "nanoimprint," a low-cost nanofabrication technique Chou invented 16 years ago, which embosses nanostructures over a large area, like printing a newspaper.

Besides the innovative design, the work involved optimizing the system. Getting the structure exactly right "is critical to achieving high efficiency," Ding says.

Chou says that the development could have a number of applications depending on the type of solar collector. In this series of experiments, Chou and Ding worked with solar cells made from plastic, called organic solar cells. Plastic is cheap and malleable and the technology has great promise, but it has been limited in commercial use because of organic solar cells' low efficiency.

In addition to a direct boost to the cells' efficiency, the new nanostructured metal film also replaces the current ITO electrode that is the most expensive part of most current organic solar cells.

"PlaCSH also is extremely bendable," Chou says. "The mechanical property of ITO is like glass; it is very brittle."

The nanostructured metal film is also promising for silicon solar panels that now dominate the market. Because the PlaCSH sandwich captures light independent of what electricity-generating material is used as the middle layer, it should boost efficiency of silicon panels as well. It also can reduce the thickness of the silicon used in traditional silicon solar panels by a thousand-fold, which could substantially decrease manufacturing costs and allow the panels to become more flexible.

Chou says the team plans further experiments and expects to increase the efficiency of the PlaCSH system as they refine the technology.

learn more on topics covered in the film

see the video

read the script

learn the songs

discussion forum