forum

library

tutorial

contact

Partners Celebrate Win-win at Hatchery

by StaffBPA Journal, June 2014

|

the film forum library tutorial contact |

|

Partners Celebrate Win-win at Hatcheryby StaffBPA Journal, June 2014 |

Fewer kilowatt-hours in, more fish out, both numbering in the millions. That's the equation for success at Dworshak National Fish Hatchery near Orofino, Idaho. Nearly 100 people gathered April 18 at one of the most remote and spectacular locations in the Federal Columbia River Power System to celebrate the win-win-win-win-win of an unusual five-way partnership.

Fewer kilowatt-hours in, more fish out, both numbering in the millions. That's the equation for success at Dworshak National Fish Hatchery near Orofino, Idaho. Nearly 100 people gathered April 18 at one of the most remote and spectacular locations in the Federal Columbia River Power System to celebrate the win-win-win-win-win of an unusual five-way partnership.

Among the crowd were leaders and staff of a tribe, a state and three federal agencies that together leveraged their diverse know-how and resources in an effort to save valuable energy and invaluable fish runs, both originating in North-Central Idaho and fanning out across the region and beyond. Chairman Silas Whitman of the Nez Perce Tribe, which co-manages the hatchery, said the unique collaboration was an example of "the cycle of life ... and an effort I hope continues to build and build and build."

Administrator Elliot Mainzer of BPA, which funded about $600,000 in hatchery improvements, agreed that the cooperation behind the innovative project became "a positive feedback mechanism in which one good act spurs another good act, and creates a cycle of virtue." Other partners included the state of Idaho; the U.S. Army Corps of Engineers, which owns and operates the dam; and the U.S. Fish and Wildlife Service, which manages the hatchery with the tribe.

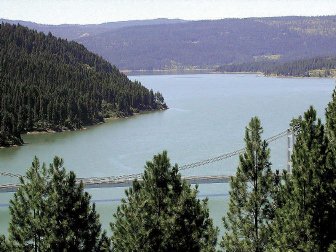

Dworshak Dam and National Fish Hatchery sit at the confluence of the mainstem Clearwater River and its North Fork, a place so propitious, people have gathered there to fish since time immemorial. On one riverbank lies the heritage site where the Nez Perce helped hungry members of the Lewis and Clark expedition build five dugout canoes for their journey down the Clearwater, Snake and Columbia rivers to the Pacific in the fall of 1805.

Two centuries later, the synergistic setting has continued to provide a rich confluence of intergovernmental cooperation and opportunity.

Thanks to energy efficiency and related refurbishments, paid for by BPA ratepayers across the Northwest since 2011, the hatchery has roughly doubled the number of fish it raises while using about half the water and energy.

The efficiency measures resulted in $431,000 in direct cost avoidance to BPA in both 2011 and 2012, meaning the project paid for itself in less than 17 months while helping the hatchery meet its production targets.

The improvements fit into the larger effort by BPA and its federal partners to rebuild threatened and endangered fish runs and to mitigate for effects of the 31 federal dams in the Columbia River Basin. This year's forecasts for fish returns to the mouth of the Columbia River are generally on the rise. They include an estimate of 227,000 spring chinook -- exceeding the 10-year average -- as well as 1.5 million fall chinook, 638,000 coho, 281,000 steelhead and 347,000 sockeye salmon.

The Dworshak hatchery was built in 1969 to offset the impact on North Fork steelhead from construction of the third-tallest dam in the U.S. At 717 feet, it is far too tall for fish passage. The facility shoulders a hefty roster of responsibilities every year: to rear and release 3.6 million young fish, including 2.1 million summer steelhead and 1.5 million spring chinook, fulfilling targets under the Lower Snake River Compensation Plan and various objectives of the Federal Columbia River Power System. The hatchery produces another 300,000 coho through a tribal program.

Partnering with the nearby Clearwater Hatchery, operated by the Idaho Department of Fish and Game, the hatchery was able to access a superior water supply from the reservoir behind Dworshak Dam, saving energy and reducing disease. The reservoir water is not only cleaner, but less chilly, flowing down at a temperature closer to ideal for rearing fish than supplemental water pumped up from the river.

"The biological gains and energy savings we made by being able to stay on reservoir water are fantastic," said Scott Bettin of BPA's Environment, Fish and Wildlife group.

The entire project reflects a more nuanced and integrated way of operating.

"The level of cooperation achieved among the partners would have been almost unimaginable only a few years ago," said aquatic engineer Jack Christiansen of the USFWS. "And it has created a new model that is directly applicable to other fish hatcheries nationwide."

learn more on topics covered in the film

see the video

read the script

learn the songs

discussion forum